Applications

Constant Velocity joint is an important component in the transmission system. Its function is to transit the power generated from the engine from transmission to wheels while reducing the bump of the suspension.

There are many types of C.V. joints. The most widely used are BJ, TJ& DOJ types.

The main parts of C.V. joints are machined by precise forging processing due to the heavy loading in operation.

PRODUCT SELLING POINT

|  |  | |

| EXTENDED LIFESPAN | DURABLE C.V. BOOT | SIMPLY INSTALLATION AND MAINTENANCE |

APPLICATION TECHNOLOGY

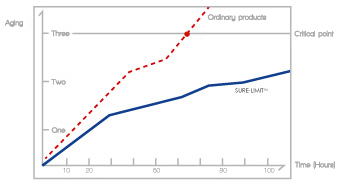

1.SURE-LIMITTMTECHNOLOGY

| Most C.V. joint failed from the aging and breakage of the C.V. boot. Our development focused on the aging of C.V. boot in tough temperature conditions. To solve the problem of cracking and aging of C.V. boot in tough temperature condition (-40 ℃-100 ℃), we developed SURE-LIMIT technology with special formulated materials. It effectively solve the aging of C.V. boot under extreme temperature conditions. | 1. Ozone concentration 200pphm 2. temperature of 40 ℃ 3. hours> 72 hours 4. tensile rate of 20% 5. no cracking |  |

| DURABLE C.V. BOOT |  |

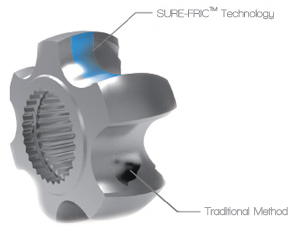

2.SURE-FRICTMTECHNOLOGY Focus on improving the friction coefficient and the lubrication of the frictional surface, SURE-FRIC technology can enhance the anti-friction ability and effective lubrication and cooling. This improvement effect of this technology on the high-strength torque output of electric vehicle drive shafts is remarkably evident. Our experimental data shows that by applying the SURE-FRIC technology to the parts, the overall service life extended by over 20% as compared to the traditional process. EXTENDED LIFESPAN |  |

SERVICE SELLING POINT

| Coverage for all car series applications |

| Proprietary technology extends the service life of special vehicle model products |

| Personalized financial support solution |

| Global strategic alliance to provide timely and efficient services |